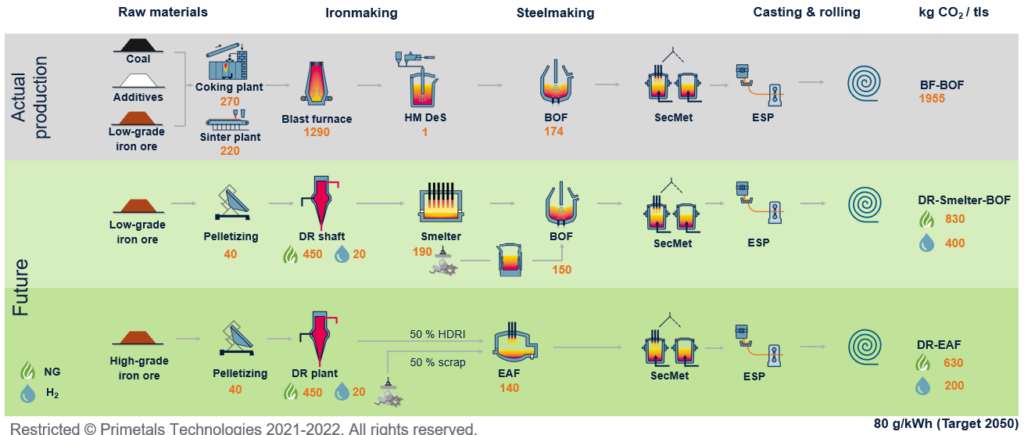

The InSGeP project, titled “Investigations of Slags from Next Generation Steel Making Processes”, is a European research initiative co-funded by the EU Research Fund for Coal and Steel (RFCS), launched on 1st July 2023. As the steel industry prepares for the transformation of the steelmaking process to reduce CO2 emissions using direct reduced iron (DRI) with varying reduction degrees, hot briquetted iron (HBI), hydrogen plasma smelting reduction (HPSR), or electrical smelters for low-grade ores, it is crucial to understand the by-products, such as slag, to uphold the commitment to zero waste.

The InSGeP project aims not only to identify the types of slags that can be expected in future steelmaking processes but also explore and investigates potential paths for their valorization within the existing value chain. Innovative applications will be defined to ensure a smooth transition process without disrupting the steel industry and other sectors, such as road construction or cement production, which currently rely on slag as a raw material for their operations.

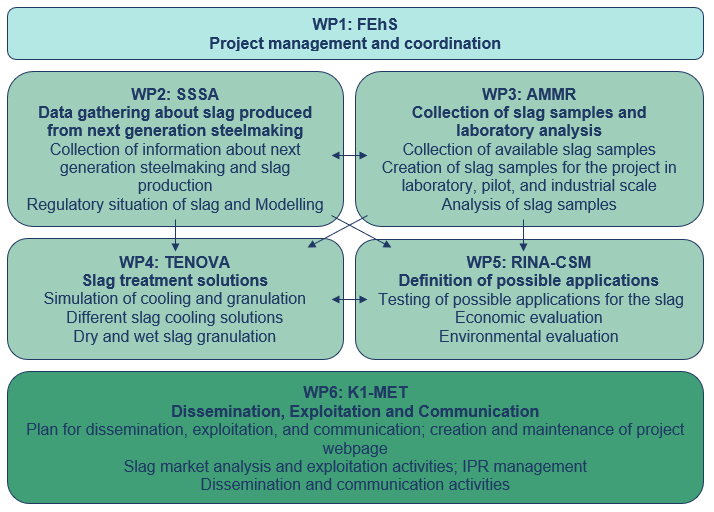

The following presents the workpackages of the project:

The project brings together 13 partners from Austria, Belgium, France, Germany, Italy and Spain, including 5 steelworks, 6 research and technology organizations (RTOs), and 2 suppliers. The project will utilize the limited amount of currently produced slags from next-generation steel production in Europe, along with conducting laboratory, pilot-scale, and industrial-scale tests based on the requirements of the involved partners. The slags will be evaluated based on their chemical, mineral, environmental, and physical properties, and different cooling and granulation methods will be employed to achieve the desired physical characteristics for various applications and environmentally compatible products. The use of slags in applications such as road construction, cement/concrete production, liming material, or 3D printing will also be tested.